- Overview

- Specifications

- Features

Description and Application

Diamond calibrating disc is designed to calibrate or remove stock on quartz stone surface to get fixed thickness and prepare for next grinding and polishing steps.

Surface calibration is the first step in quartz stone polishing and it is fundamental important in the quartz stone processing and usually the calibration are done on both the top and bottom of the slab. It helps eliminate defects formed during moulding.

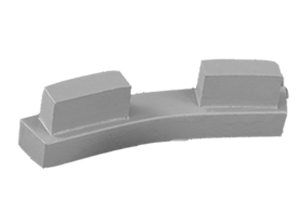

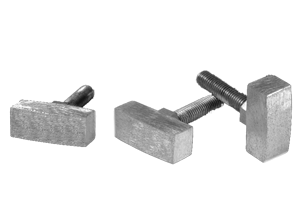

Currently two designs of segmented calibrating discs are common in use, one with two segments welded onto a steel plate and the other with one segment welded onto one threaded bolt to be fixed onto calibration disc plate.

Features and Advantage

High sharpness with aggressive calibration and stock removal capacity,

High Calibration efficiency and long lasting life in quartz stone calibration;

Grain Sizes Available

24#, 36#, 46#, 60#, 80#, 120#

Success Story:

Serving several polishing lines of Quartz Stone factory in southern China, polishing quartz stones of various colors and hardness with different composites, with fast aggressive calibration and stock removal, high calibration efficiency and excellent thickness calibration.

Keywords and Tags

Calibration Disc, Diamond Calibrating Disc, Calibrating Disc, Calibration Wheels, Calibrating Wheels, Diamond Grinding Wheels, Quartz Stone Calibration Disc, Quartz Stone Calibrating Disc, Calibrating Plate, Quartz Stone Abrasives, Quartz Stone Grinding Abrasives, Quartz Stone Polishing Abrasives, Polishing Abrasives for Quartz Stone, Composite Stone Abrasives, Composite Stone Grinding Abrasives, Composite Stone Polishing Abrasives, Stone Polishing Abrasives, Stone Polishing Abrasives, Diamond Tools for quartz stone, diamond abrasives for quartz stone, Fullux Abrasives

Frankfurt Diamond Abrasive

Frankfurt Diamond Abrasive